Vinyl Skirting

Vinyl skirting is the most popular for a few reasons: it is easy to install, not hard on the wallet and very attractive. Most kits run about $600 and up for a basic sized single wide and will include all the pieces you need to completely skirt the entire home. There’s 4 basic pieces needed for vinyl skirting:

Vinyl skirting is the most popular for a few reasons: it is easy to install, not hard on the wallet and very attractive. Most kits run about $600 and up for a basic sized single wide and will include all the pieces you need to completely skirt the entire home. There’s 4 basic pieces needed for vinyl skirting:

- The panel itself which is sold in 12 foot lengths. This is to make it easy for homes that are sitting on an incline, you simply cut the panels at the right dimension you need for the area. You can start at 2′ on one side and end up with 12″ on the other. You’ll need to use the average height method to order the correct amount of skirting.

- The ground track which is what is bolted into the ground with long rods. It is U-shaped channel and the panel will fit down into it and keep is secured.

- The top back is what goes on the bottom of the home before the panels are set into place. It has a top J channel that the top front piece will fit into.

- The top front piece is the horizontal strip in front of the panel. It gives the entire system a more polished appearance and allows the skirting more security. It’s the last part you add.

Vinyl usually comes in 11’8″ panels, although they call them 12′ panels. You should buy all you need in one lot plus an extra panel or two. The dying process is not 100% accurate so there could be mismatching of the color even though you are ordering the same color.

Vinyl siding and skirting is very environmentally friendly, unfortunately it is misunderstood by a lot of people. Most think vinyl comes from oil and the refining process, but that is incorrect. All vinyl productions start with two simple and abundant building blocks –chlorine from common salt and ethylene from natural gas. According to Building for Environmental and Economic Sustainability (BEES) software, vinyl siding out performs brick, stucco and wood on how it affects the environment based on a combination of environmental criteria.

The disadvantages of vinyl is that it does not do well with weed-eaters. There are guards you can add to remedy that though. Storms and high winds can also be an issue.

Reil Rock Skirting Panels

The second most popular skirting options are Reil Rock panels. They are made of sturdy plastic, have the look of stone and come in 3 colors. They come in 5 foot sections with 3 height options: 2’6″, 3′ and 4′. They are very easy to install because you simply use a U channel or J channel on the ground and screw the panel into a board attached to the home (some just attach directly to the home and some don’t even use the ground channel). There is a track you can put over top of the panel, but it’s not needed either. If your panel is just shy a couple of inches you can use the top track to cover the issue. A 5 foot panel is more expensive than vinyl but it’s sturdier and can handle a bit more weed-eater abuse.

The second most popular skirting options are Reil Rock panels. They are made of sturdy plastic, have the look of stone and come in 3 colors. They come in 5 foot sections with 3 height options: 2’6″, 3′ and 4′. They are very easy to install because you simply use a U channel or J channel on the ground and screw the panel into a board attached to the home (some just attach directly to the home and some don’t even use the ground channel). There is a track you can put over top of the panel, but it’s not needed either. If your panel is just shy a couple of inches you can use the top track to cover the issue. A 5 foot panel is more expensive than vinyl but it’s sturdier and can handle a bit more weed-eater abuse.

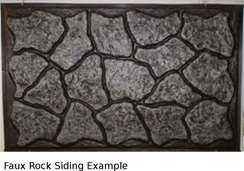

Faux Rock or Brick Panels"

Most faux panels are made from a polyurethane and come in 46 ¼” wide × 24″ high × 1 ¼” thick panels. They look remarkably like real stone. You can frame the area to be skirted with 2×2 or 2×4′s and then screw the panels into the frame. You can also completely frame the area with plywood and screw onto that for a sturdier installation. They are light but sturdy, and they can withstand temperature fluctuations very well.

Most faux panels are made from a polyurethane and come in 46 ¼” wide × 24″ high × 1 ¼” thick panels. They look remarkably like real stone. You can frame the area to be skirted with 2×2 or 2×4′s and then screw the panels into the frame. You can also completely frame the area with plywood and screw onto that for a sturdier installation. They are light but sturdy, and they can withstand temperature fluctuations very well.

They are a bit expensive but cheaper than real stone and much easier to install.

Metal Skirting

Metal can be steel or tin. Both are great products that are affordable. Simple installation is an added advantage. A simple 2″x4″ frame with the panels attached by screws or nails (rust free only). You can also attach the top of the panel to your home via attached board (or straight to the frame) and then dig a channel in the ground and back fill the ditch. It’s quick and easy and the dirt can’t hurt it at all.

Metal can be steel or tin. Both are great products that are affordable. Simple installation is an added advantage. A simple 2″x4″ frame with the panels attached by screws or nails (rust free only). You can also attach the top of the panel to your home via attached board (or straight to the frame) and then dig a channel in the ground and back fill the ditch. It’s quick and easy and the dirt can’t hurt it at all.

These days the designs for metal mobile home skirting are getting more attractive, too. The old cinder block or large brick stamped pattern has been the most popular design but with a little research you can find new patterns.Metal mobile home skirting can be easily painted.

Metal can withstand a weed-eater which is always a plus.

Concrete, Brick, and Cinder Block Skirting

If you want performance, permanence concrete, brick, or cinder block is probably your best choice. Adding brick or cinder block to a home is a labor intensive ordeal, but the advantages are worth it. Being practically indestructible is it’s best advantage. Concrete panels are easier to install but has similar indestructibility and longevity as brick and cinder block. We can install concrete skirting but you can purchase precasted concrete panels, too. There’s a little misunderstanding surrounding cinder block and brick skirting and ‘permanent foundations’ for mobile and manufactured homes. FHA loans requires that all manufactured homes be permanently installed but that has little to do with the skirting material. A manufactured home can be permanently installed and have vinyl skirting. Permanent installation is about the ties, not the skirting.

Foam Skirting

Foam skirting is sometimes called “Insulated Vinyl Skirting” or “Rigid Foam”. The claim is that they will reduce underside energy loss by up to 22%. You can get them in different colors and textures, like fine pebble or brick. This skirting can be used alone with a kit or frame or as added insulation in front or behind other skirting solutions.

You can get complete framing solutions that act like frames, but have channels to put the foams into. Most suppliers recommend this. The price on the panels is approximately $10-15 per foot. The installation kits depend on the linear foot needed. One company has an entire kit for about $650 (just for the installation kit, the panels are bought separately).

Plywood, OSB and T-111 Skirting

Wood has always been a well known construction material. Using wood for skirting isn’t the best option unless it’s treated. It’s susceptible to rot and insects otherwise. Hardiboard and OSB are very sturdy. OSB is cut with the trees grain and the engineered together to make a very strong product.

Wood products that are not waterproof are going to get swelling from moisture. Price depends on what you chose and installation can be simple or complicated. Some people suggest that you use a sealer and caulk the ends of the boards before putting them up just as an added precaution against moisture. You can use planks and get the look of siding, too. Lots of potential with wood!

Other Skirting Options

- Metal roofing is a good choice. It’s relatively affordable for the size and it’s water, rot and insect proof. if it can handle being on a roof, it can handle being used as skirting!

- Old barn tin has already stood the test of time and it’s gorgeous. One of our featured homes has antique barn tin as a skirting, and it is gorgeous! I guess this should qualify under the metal options, but hey, it’s antique!

- Railroad ties work, I’ve seen it and it was a very nice look. I bet the installation was labor intense but the insulation qualities have to be great.

- Soffet is cheap and can work well with the proper framing. It comes in different colors and is remarkably similar to vinyl.

- Corrugated fiberglass has been used for mobile home skirting for years. There’s a nice white you can buy and with the proper framing it would last for years. Not sure about the insulation value.